Beer, a drink that is more popular than the mighty coffee itself! Beer is the third most consumed and popular drink after water and tea. One of oldest alcoholic drink, the popularity of beer seems to be ever rising even today. The Mesopotamians even had a goddess of beer, can you imagine?

Traditionally, beer was made by a process called brewing. The building or the station used for the purpose was called a brewery. Where large scale brewing takes place at an industrial scale.

On the other hand micro brewing plants help you process beer at a domestic level let you experiment and modify the recipe as for experimentation with brewing. These are frequently employed at pubs and restaurants where the outlets prefer their own fresh brewed beer than the available brands.

So how does a micro brewing station work?

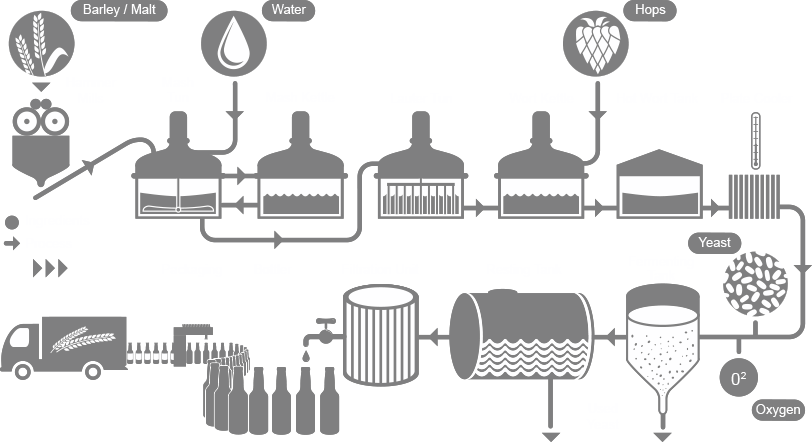

The ingredient grain i.e. barley along with a secondary source of starch such as corn or rice is added in a measured quantity and grinded into a mash. This would later be mixed and agitated in a boiling water tank. The temperature is controlled to allow fermentation and release of fermentable sugar namely ‘maltose’. The end result of this is the product we call ‘wot’. Temperature can be altered along with the mineral content of the water to adapt different styles of beer.

The second step in brewing is called ‘lautering’ or ‘wot separation’. Where the spent grains are separated from wot. The filtered contents are almost grain husks and other solids. The filtered wot is taken to the next step in the brewing process. This process is facilitated using water sparges and filtered simultaneously. A second or third wash of the grains can be also done.

Third step is the transfer of the wot into the ‘wot kettle’ or the boiling of the wot liquid which imparts color and the bitterness along with the popular aroma of beer. The heat even sterilizes the wot making sure your beer is germ free before addition of the yeast for fermentation.

The fermentation process takes anywhere between few weeks to months depending upon the strength of beer. It releases carbon dioxide and ethyl alcohol. Whirl pooling is done to settle the solids alongside the fermentation process. Sometimes a secondary fermentation process can be included in the brewing process depending on the taste requirement and for longer storage

Fruit flavors and other specific agents can be added in microbrewing stations to produce unique styles.